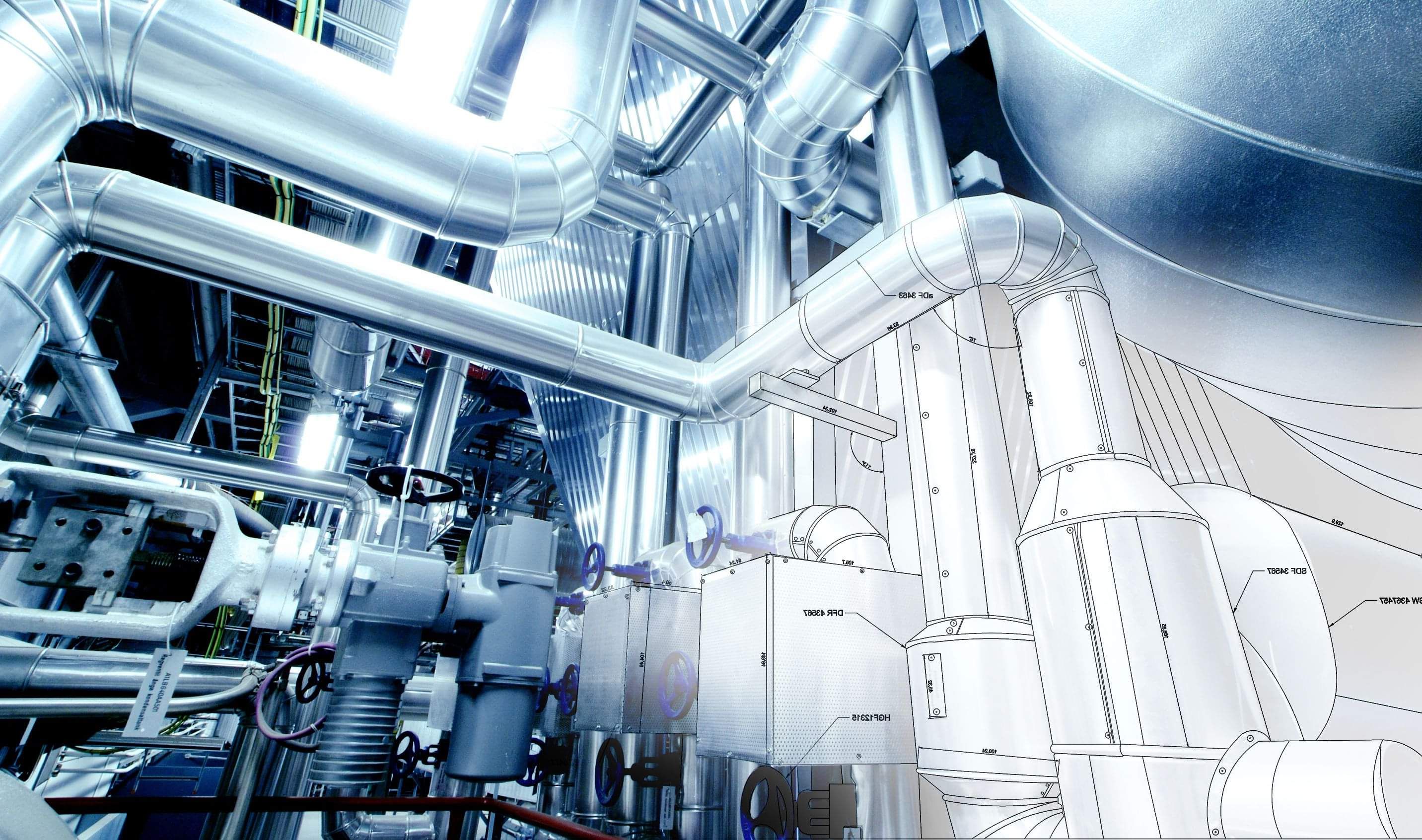

Process Engineering ————

From process design through to operations and on-site support, Provantage Engineering delivers a comprehensive range of process engineering services.

With quality and value at the forefront, our experienced technical team supports projects across all phases, providing practical engineering solutions and ongoing operational support throughout the life of the plant.

We have a proven track record of supporting projects and operating assets across their full life cycle, from concept development through to operations, within the oil and gas and petrochemical sectors.

Advice throughout the project lifecycle ————

Process engineering is an investment for success, to ensure that expectations are achieved, and unintended consequences are avoided for people, plant and the environment. Provantage Engineering can provide support at all stages of the project lifecycle.

CONCEPT SELECT

From feasibility assessment and capital and operating cost estimation through to the evaluation of health, safety, and environmental impacts, Provantage Engineering provides a comprehensive range of concept selection services, including:

Concept design development

Feasibility studies

Technology screening and recommendations

Capital and operating cost estimates

Health, Safety and Environmental (HSE) impact assessments

DESIGN

Utilising the best simulation tools and design methods, Provantage Engineering offers a range of process engineering design services during FEED and detailed design. We can develop best practice designs, estimate costs accurately and bring all disciplines together including any specialist vendors required.

Process simulation

Mass and energy balances

Unit operations e.g. separation, distillation, reactors

Heat transfer - heat exchangers, heaters, coolers, heat loss

Hydraulic design - line sizing, pump specifications, control valves

Process control and optimisation

Relief and venting

Utility systems

OPERATIONS / ON-SITE SUPPORT

Provantage Engineering provides a comprehensive range of operational and on-site support services to ensure safe, reliable, and optimal plant performance. Our services include equipment troubleshooting, plant optimisation and debottlenecking studies, and commissioning and operator training for new or modified facilities.

Our operational and on-site support services include:

Plant optimisation

Debottlenecking studies

Equipment and process troubleshooting

Brownfield integration for plant extensions and upgrades

Commissioning support

Operator training

PROCESS ENGINEERING ASSURANCE

Provantage Engineering provides a range of engineering assurance services, including independent verification of third-party designs, advice on engineering best practice, and acting as Owner’s Engineer on behalf of clients. This includes undertaking independent assessments of Safety Critical Elements (SCEs) in accordance with WorkSafe New Zealand requirements.

Our assurance services include:

Process design assurance

Independent verification and assessment

Safety Critical Element (SCE) independent assessment

Owner’s Engineer services

Engineering best practice advice

Safety case support