Multi-Discipline Engineering ————

Provantage Engineering offers a broad range of complementary engineering services that support and enhance our core process engineering capability. These include functional safety engineering, Instrumentation and Electrical (I&E) engineering, and rotating equipment support across design, procurement, and commissioning.

Through collaboration with our trusted partners, we provide access to multi-discipline engineering capability for hydrocarbon and petrochemical facilities. We apply best practice in accordance with applicable codes, standards, and legislative requirements, utilising industry-leading tools and technologies to support effective and seamless project delivery.

Specialist expertise for your project ————

FUNCTIONAL SAFETY ENGINEERING

Process Safety Instrumented Systems (SIS) comprise multiple Safety Instrumented Functions (SIFs) designed to place a plant or process unit into a safe state in response to abnormal or hazardous conditions. These functions form active layers of protection and are required to operate automatically when defined limits are exceeded. The IEC 61511 standard defines the functional safety lifecycle governing the specification, implementation, operation, and management of these functions.

Provantage Engineering provides specialist functional safety expertise across the full project lifecycle, from concept development through to operation and decommissioning. Our services are delivered in accordance with the requirements of IEC 61511 and are tailored to suit project, operational, and regulatory needs.

Our functional safety services include:

Functional Safety Management

Development and review of Functional Safety Management (FSM) plans

Functional safety audits, assessments, and independent verification

Risk Reduction Support

Support for and technical review of HAZOP and LOPA studies

Safety Requirements Specification

Development and review of Safety Requirements Specifications (SRS)

Safety Instrumented Systems Design

Design and engineering of Safety Instrumented Systems (SIS) and Safety Instrumented Functions (SIFs)

PFDavg calculations using fault tree analysis and other recognised methodologies

Lifecycle and Operational Support

Support during installation, commissioning, validation, and ongoing operation

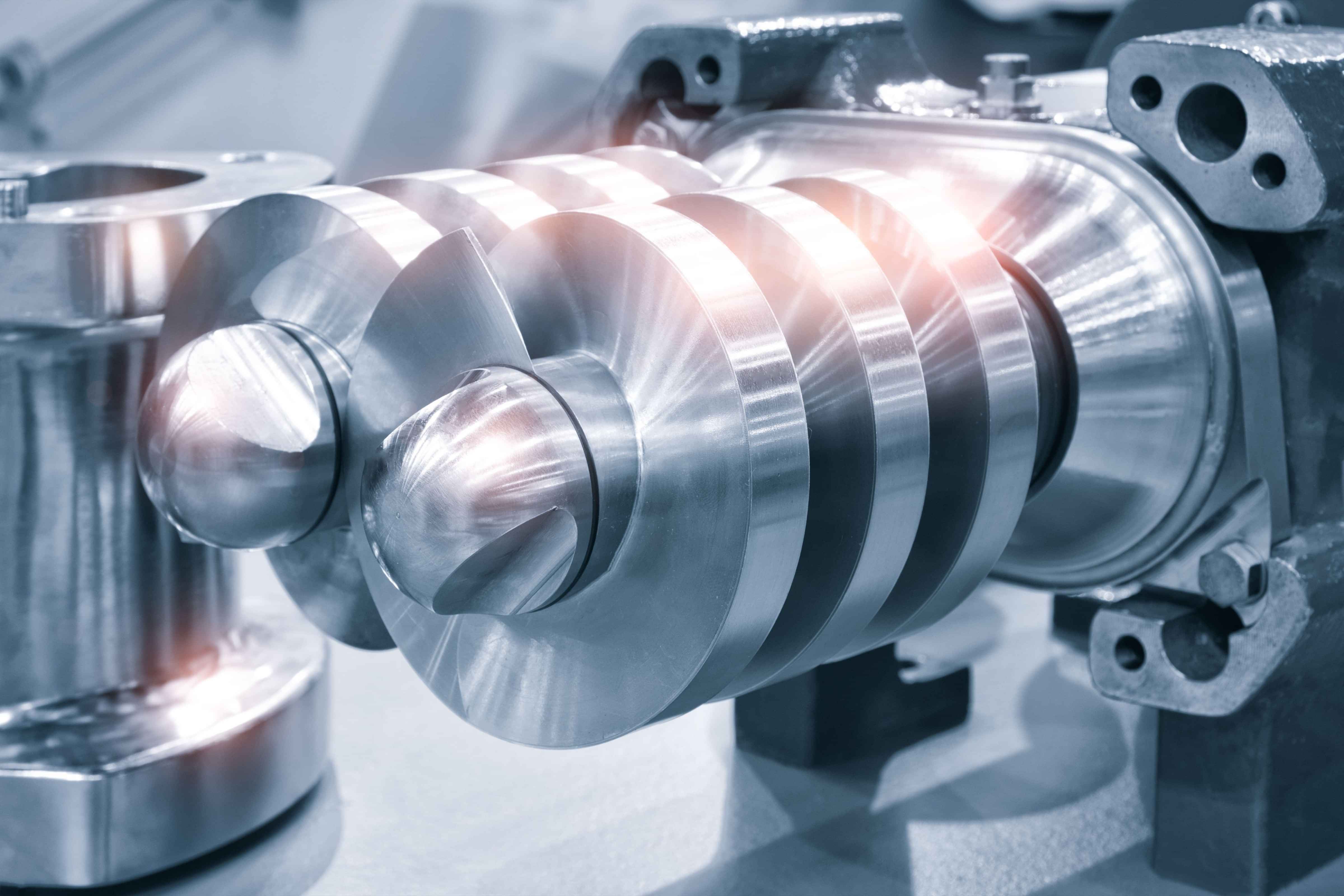

ROTATING EQUIPMENT ENGINEERING

Rotating equipment is critical to the safe, reliable, and efficient operation of process facilities, from compressors and pumps through to turbines and engines. Correct specification, procurement, installation, and ongoing maintenance are essential to achieving design performance and long-term reliability.

Provantage Engineering provides rotating equipment engineering support across the full project and asset life cycle, from concept development through to installation, commissioning, and operational support.

We offer expertise across a broad range of rotating equipment, including:

Centrifugal, reciprocating, and screw compressors

Centrifugal and positive displacement pumps

Multiphase pumps

Firewater pump sets

Gas turbines and engines

Concept Development and Feasibility

Equipment feasibility assessments

Equipment selection and recommendations

Capital and operating cost input

Reliability and maintenance impact assessment

Package Engineering

Equipment specifications and datasheets

Technical prequalification and bid evaluation

Third-party inspection coordination and monitoring

Factory Acceptance Testing (FAT) support

Documentation review and approval

Construction, Installation, and Commissioning

Installation and commissioning procedures

Storage and preservation requirements

Grouting specifications

Pre-commissioning and commissioning support

Operational Support

Equipment troubleshooting and performance assessment

Reliability improvement and operational support

INSTRUMENTATION & ELECTRICAL ENGINEERING

Instrumentation and Electrical (I&E) systems are fundamental to the safe, reliable, and efficient operation of process facilities. Provantage Engineering provides experienced I&E engineering support across the project and asset life cycle, with a focus on sound engineering judgement, operability, and integration with process and safety requirements.

Our I&E services are delivered by senior engineers and are tailored to suit both project and operational needs. We support concept development, front-end engineering, technical assurance, and site activities, working closely with designers, vendors, and EPC partners where detailed drafting or package design support is required.

Our I&E engineering services include:

Instrumentation and control philosophy development

Control system and instrumentation specification input

Field instrumentation selection and application support

Fire and gas detection system philosophy and layout input

Alarm management philosophy and rationalisation support

Electrical engineering input and interface coordination

Vendor package review and technical assurance

Commissioning, testing, and operational support

This approach allows Provantage Engineering to provide practical, high-value I&E engineering input while integrating seamlessly with multi-discipline project teams and specialist partners.

MULTI-DISCIPLINE ENGINEERING

Where project requirements extend beyond our in-house capability, Provantage Engineering works with a network of trusted engineering partners to provide access to additional engineering disciplines. This approach allows us to support multi-discipline project needs while retaining a clear focus on technical oversight, integration, and interface management.

We assist clients by coordinating and reviewing specialist mechanical, civil, structural, electrical, and other discipline inputs as required, supporting project delivery across defined scopes and phases.